Switching between vacuum and reflow modes to enable various production forms

- Can also be used as a normal reflow oven by switching modes

- The heating method of the vacuum zone is renovated to support large workpieces

- Evolved transfer type that can reproduce various temperature profiles

- Vacuum control mechanism enables scattering control and void-free performance

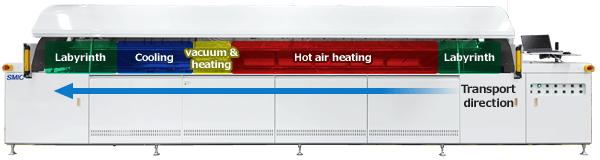

Furnace configuration

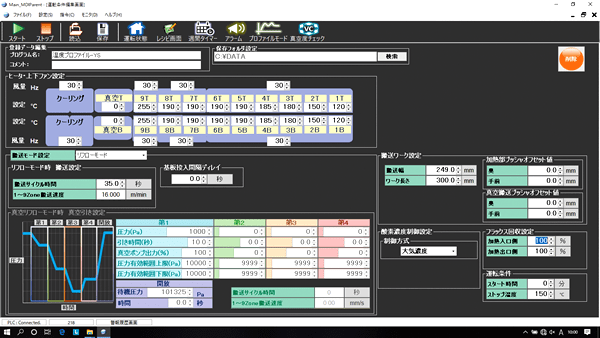

The operation screen that allows easy mode switching and vacuum settings

Vacuum & heating zone that enable various production forms

Notebook PC display panel

3D display for easy operation

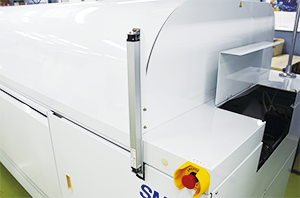

Safety light curtain

Improved maintenance safety

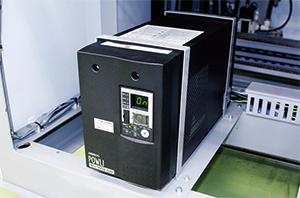

UPS power supply

Safe stop in the event of a power outage

Other equipment

- PLC + PC control

- Heated zone flux management system

- PCB fall detection

- PCB counter

- Oxygen analyzer

- Automatic oxygen concentration control

- Independent fan control (tripartition)

- Profile measurement mode

- Weekly timer

- Conveyor special surface treatment(chain, key materials and sprockets)

- Signal tower

- Automatic conveyor width adjustment

- Chiller unit

Automatic changeover by bar code [optional]

Functions that enable changeover without errors

Other equipment

- Up/down mechanism of top-bottom labyrinth curtains

- All block fan control

- Operator/engineer mode

- Display in English, or Chinese

| SVR-1040GT-PC | ||

|---|---|---|

| Dimensions (L×W×H) | 6,900 × 1,760 × 1,475 mm | |

| Conveyor height | 900 ±20mm | |

| Transfer form | pin chain & pusher | |

| PCB dimensions | W:100 - 400, L:120 - 400, T:1.0 - 3.0 mm | |

| Component height | ≦10mm [OP:50mm], ≧15mm [OP:25mm] | |

| Heating zone | 9 | |

| Vacuum zones | 1 | |

| Cooling zone | 2 | |

| Side edge clearance | 5mm | |

| N2 (Nitrogen) gas supply | Main | ≧99.999%, ≧0.4MPaG, max. 600NL/min |

| Vacuum break | ≧99.999%, ≧0.4MPaG, max. 1,000NL/min(Vacuum breaking time:8sec) | |

| N2 (Nitrogen) gas usage | Component height/STD:≦10mm, ≧15mm | 600NL/min |

| Power requirement | 200V, max52KW, 135A, 3-phase | |